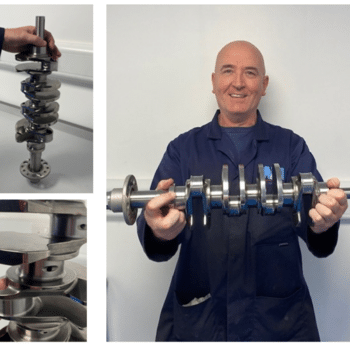

Complex components and tooling developed through advanced R&D and DFM consultancy

Supporting manufacturers around the world who demand fast precision

Supporting manufacturers around the world who demand the highest tolerances

A&M’s in-house R&D, materials knowledge and process insight complement our manufacturing skills to help deliver exceptional design for manufacture solutions.

Latest News

To see how A&M could support your next complex manufacturing project – simply call us, or use the form below.